Research Article Failure Modes and Empirical Relations to Design Piston Pins for IC Engine

Analysis of piston pin

DOI:

https://doi.org/10.54060/jmce.v3i2.39Keywords:

piston pin, internal combustion engine, axial crack, circumferential crackAbstract

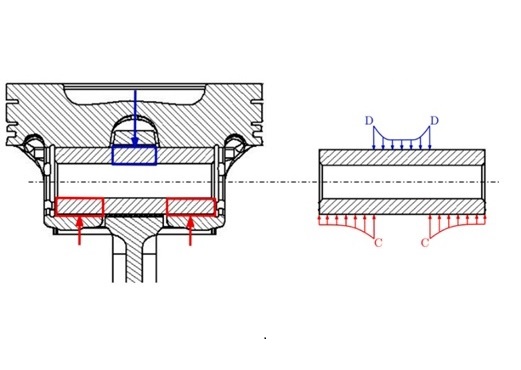

In this article, authors discussed the various boundary conditions (fully floating, semi floating and stationary) and failure modes (transverse crack and longitudinal crack) of piston pin of IC engine. Moreover, authors given the empirical relations for shear stress, bending stress and ovalization stress to design piston pin for internal combus-tion engines. Furthermore, carried out the force analysis on piston pin and expressed the empirical relations for force analysis of piston pin that will be very useful for de-sign of piston pin for petrol and diesel engines.

Downloads

References

A. Strozzi, A. Baldini, M. Giacopini, E. Bertocchi, and S. Mantovani, “A repertoire of failures in gudgeon pins for in-ternal combustion engines, and a critical assessment of the design formulae,” Eng. Fail. Anal., vol. 87, pp. 22–48, 2018. https://doi.org/10.1016/j.engfailanal.2018.02.004.

C. Wen, X. Meng, Y. Xie, R. Liu, X. Kong, R. Li, & C. Fang, “Online measurement of piston-assembly friction with wire-less IMEP method under fired conditions and comparison with numerical analysis,” Measurement, 174, 109009. https://doi.org/10.1016/j.measurement.2021.109009.

R. Karwa, A textbook of machine design. Firewall Media, 2019.

L. Bianco, S. G. Barbieri, V. Mangeruga, M. Giacopini, and G. Capoccia, “Influence of the thermal deformation on the lubricating performance of the piston-gudgeon pin interface in an internal combustion engine,” Tribol. Int., vol. 174, no. 107719, p. 107719, 2022. https://doi.org/10.1016/j.triboint.2022.107719.

A. Vijayvergiya, E. Kumari, and S. Lal, “Design and shape optimization of connecting rod end bearing through ANSYS,” International Research Journal on Advanced Science Hub, vol. 3, no. 11, pp. 235–242, 2021. DOI: 10.47392/irjash.2021.261

E. Kumari, J. Singh, and G. Kasera, “Analysis of piston of internal combustion engine under Thermo-mechanical load,” International Research Journal on Advanced Science Hub, vol. 3, no. Special9S, pp. 11–18, 2021. DOI: 10.47392/irjash.2021.242

E. Kumari and D. Saxena, “Buckling analysis of folded structures,” Mater. Today, vol. 43, pp. 1421–1430, 2021. https://doi.org/10.1016/j.matpr.2020.09.179.

E. Kumari, “Dynamic response of composite panels under thermo-mechanical loading,” J. Mech. Sci. Technol., vol. 36, no. 8, pp. 3781–3790, 2022. DOI: 10.1007/s12206-022-0701-x

E. Kumari and S. Lal, “Nonlinear bending analysis of trapezoidal panels under thermo-mechanical load,” Forces Mech., vol. 8, no. 100097, p. 100097, 2022. https://doi.org/10.1016/j.finmec.2022.100097.

E. Kumari, M. Sharma and P. M. Meena, “Research article A parametric study to improve the heat transfer of solar air heater through CFD analysis,” J. Mech. Constr. Eng., vol. 2, no. 2, pp. 1–17, 2022.

A. Kolchin and V. Demidov, Design of Automotive Engines. Moscow: Mir Publishers, 1984.

K. Clark, J. Antonevich, D. Kemppainen, and G. Barna, “Piston pin dynamics and temperature in a C.i. engine,” SAE Int. J. Engines, vol. 2, no. 1, pp. 91–105, 2009. https://doi.org/10.4271/2009-01-0189.

V. Debnath and B. Debnath, “Deflection and stress analysis of a beam on different elements using Ansys APDL,” International Journal of Mechanical Engineering and Technology (IJMET), vol. 5, no. 6, pp. P70-79, 2014.

H. Allmaier and D. E. Sander, “Piston-pin rotation and lubrication,” Lubricants, vol. 8, no. 3, p. 30, 2020. DOI:10.3390/lubricants8030030.

F. Shi, “An analysis of floating piston pin,” SAE Int. J. Engines, vol. 4, no. 1, pp. 2100–2105, 2011. DOI:10.4271/2011-01-1407.

Downloads

Published

How to Cite

CITATION COUNT

Issue

Section

License

Copyright (c) 2023 Dr. Emarti Kumari, Mahesh Choudhary, Brijesh Gurjar, Mahesh Bishnoi, Deepak Sharma, Hemant Jagrat, Manish, Mukesh Choudhary, Deepika Choudhary, Saroj

This work is licensed under a Creative Commons Attribution 4.0 International License.