CFD Analysis of Variable Displacement Swash Plate Type Axial Piston Pump Flat Slipper

DOI:

https://doi.org/10.54060/JMCE/002.01.001Keywords:

CFD, Optimization, Flat Slipper, Swash Plate, Groove, Clearance, SimulationAbstract

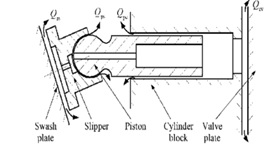

In the field of hydraulic machines, piston pumps are the only ones that can work under very high pressures and deliver best efficiency as a result of which they have very sophisticated design. As per surveys most parts of these pump have validation from experience of designers as a result of which there isn’t any mathematical tool for design optimization of different parts. Although there are now companies e.g. Oilgear Towler, who are in favor of, and them-selves inserted, slots (grooves) on the slippers and in pistons as we shall in this report, but there is no particular study to realize their benefits and drawbacks. Therefore, it is necessary to study advantages and disadvantages arising due to presence of grooves on the surface of dif-ferent parts of pump mathematically or through CFD solvers. In this project work, aim is to analyze the effect of design parameters and working conditions on the pump behavior. This is done using parametric study performed on a model of slipper and simulating the physical problem on ANSYS. As major leakage occurs between slipper and swash plate clearance there-fore in this project report static and dynamic analysis of slipper in done. The Navier Stokes Equations are solved in 3-D to acquire results using Rhie and chow method and ANSYS FLUENT solver. The various design points which effect the efficiencies of pump in a positive manner, if any, shall be discussed in the conclusion part.

Downloads

References

J. M. Bergada, S. Kumar, D. L. Davies, and J. Watton, “A complete analysis of axial piston pump leakage and output flow ripples,” Appl. Math. Model., vol. 36, no. 4, pp. 1731–1751, 2012.

“Bent axis fixed displacement axial piston pumps for open circuit,” Bondioli & Pavesi, 26-Apr-2016. [Online]. Available: https://www.bondioli-pavesi.com/en/power-transmission/axial-piston-pumps-and-motors/bent-axis-fixed-displacement-axial-piston-pumps-0. [Accessed: 21-Jul-2022].

“Manufacturing technology of swash plate axial piston pump,” Mks-hydraulic.com. [Online]. Available: https://www.mks-hydraulic.com/newsinfo/512835.html. [Accessed: 21-Jul-2022].

S. G. Ye, J. H. Zhang, and B. Xu, “Noise reduction of an axial piston pump by valve plate optimization,” Chin. J. Mech. Eng., vol. 31, no. 1, 2018. https://doi.org/10.1186/s10033-018-0258-x

“Navier-Stokes Equations,” Nasa.gov. [Online]. Available: https://www.grc.nasa.gov/www/k-12/airplane/nseqs.html. [Accessed: 21-Jul-2022].

P. Bartholomew, F. Denner, M. H. Abdol-Azis, A. Marquis, and B. G. M. van Wachem, “Unified formulation of the momentum-weighted interpolation for collocated variable arrangements,” J. Comput. Phys., vol. 375, pp. 177–208, 2018.

“ISO grade oils - viscosities and densities,” Engineeringtoolbox.com. [Online]. Available: https://www.engineeringtoolbox.com/iso-grade-oil-d_1207.html. [Accessed: 21-Jul-2022].

E. Koç and C. J. Hooke, “An experimental investigation into the design and performance of hydrostatically loaded floating wear plates in gear pumps,” Wear, vol. 209, no. 1–2, pp. 184–192, 1997.

J. Chen, J. Ma, J. Li, and Y. Fu, “Performance optimization of grooved slippers for aero hydraulic pumps,” Chin. j. aeronaut., vol. 29, no. 3, pp. 814–823, 2016.

“Turbulence modeling,” Cfd-online.com. [Online]. Available: https://www.cfd-online.com/Wiki/Turbulence_modeling. [Accessed: 21-Jul-2022].

“COMSOL: Multiphysics software for optimizing designs,” COMSOL. [Online]. Available: https://www.comsol.com/. [Accessed: 21-Jul-2022].

S. Kumar, J. M. Bergada, and J. Watton, “Axial piston pump grooved slipper analysis by CFD simulation of three-dimensional NVS equation in cylindrical coordinates,” Comput. Fluids, vol. 38, no. 3, pp. 648–663, 2009.